- 2 piece frame = quick field setup

- Hinged bolts

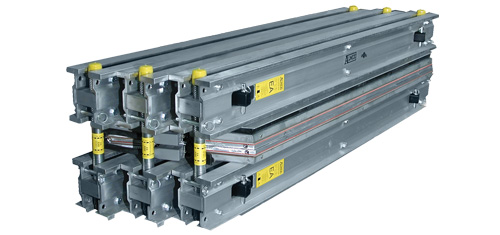

- #1 overland belt splicing press

Rectangular (AB) frame presses are well-suited for shop use for adding cleats or profiles to flat belt. The two-piece frame style can provide full access to the splice area.

- Open 2 or 4 side configuration

- For all belt widths

- well suited for profiling

Features

-

Open 2 or Open 4 side configuration

-

Can accommodate all belt widths

-

Signature Almex "Pressure Bag" uniform pressure system

-

Custom "Extruded Plank" cooling system within platens

-

Durable "Silicone Element" heating system, custom designed to voltage phase and cycle

-

Exceptional remote digital control

-

Accurate temperature control and indication

-

Can be aligned side-by-side for longer splice areas and easier handling

-

Operating pressures of 7kg/cm² (100 psi) to 14kg/cm² (200 psi)

-

Temperature Control Panels available with ground fault and ground continuity monitoring

-

Lower platen restraint

Product Information

OPTIONS

- Retractable bolts, stored in-frame

- Custom daylight

FRAME

- With rugged welded construction, the upper and lower frames of the press are ideal for both field applications in various mining environments and repetitive shop use

- The fitted rings and brackets allow this frame press to be positioned over splice areas with an overhead crane

- The top and bottom frames secure around the splice with our unique bolt/nut system

- A bolt retraction system, with the bars storing in the frame when not in use, is available as an option

PLATENS

- Each frame press is constructed with aluminum flexible platens that contour to the conveyor belt surface during splicing

- Platens are individually designed and include extruded plank, silicone heating elements-heating up to 163 °C / 325 °F, and durable composite insulating packaging

- Sturdy electrical connectors and moisture-proof latches enhance press durability and longevity

- Lower platen restraint to hold the platen in place when removing the cured belt

PRESSURE/COOLING

Suitable Pumps:

- HP25MAX

- HPP20-4

- HPPC20-4

- HPPC100

- HPPC300

- HPPC-500

Ground Fault:

- HP25MAX-GF

- HPP20-4-GF

- HPPC20-4-GF

- Optional pressure pump and reservoirs are required for operating pressures above 7kg /cm² (100 psi). Pumps have optional cooling options

CONTROL PANEL

SUITABLE CONTROLS:

- T6

- SG1

GROUND FAULT:

- T4-GF1 (BOTE)

- T4-GF2 (BOTE)

- T4P-GF1 (AS/NZS)

- T4P-GFIU (AS/NZS)

- T6GFXP