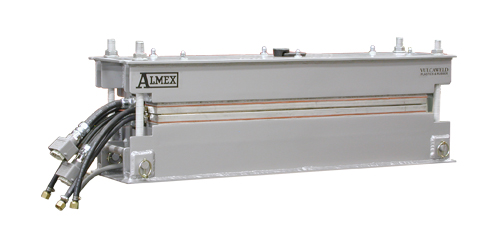

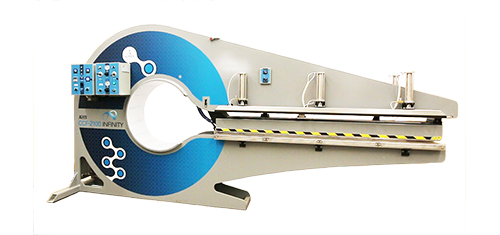

VCF Cantilever Press

Production Press – 5.3 kg/cm² (75 PSI) Maximum

The Cantilever VCF Press is the superior press for splicing lightweight rubber conveyor belting. With the increased pressure capacity of 5.3 kg/cm² (75 PSI), the Cantilever VCF is designed for rubber conveyors that do not require heavyweight splice equipment.

Features and Product Information

Features

- Hinging Upper aluminum frame

- Lower steel frame forms an integral support arm of cantilever stand

- Machined platens and frame

- FCP (frame-mounted control panel) electronic control system with programmable controllers, time and audio alarm, water cooling and air purge systems for automatic operation

- Stainless steel platens included

- Air control panel for hinging, locking and pressurization

- Available in most voltages

- Temperature variable up to 163 °C (325 °F)

- Optional higher temperatures available up to 200 °C (392 °F)

Product Information

Options:

- Clamps

- Water cooling system for faster cool down

- Cantilever upstroking lower platen for small circumference belts

Specifications

PLATENS

- Assembled with extruded plank, silicon heating element, and durable composite insulating

package

FRAME

- Steel Cantilever Frame Style for shop use. A pneumatic lift is on the upper platen, making for easier use and decreased splice time

CONTROL PANEL

- The Frame Mounted control panel (FCP) provides hinge and locking pressurization controls

- It is designed to accommodate various amp and volt requirements

- Including timer, fully automatic operation features include pressure and cooling functions

- Thermo couple leads are available to connect to the panel

PRESSURE/COOLING

- Engineered for PVC & PU belt rubber belt, the VCF has a maximum pressure of 5kg/cm2 (75psi)

- Uniform pressure is applied via the exclusive Almex pressure bag

- Down-stroking pressure is standard, but an up-stroking design is optional

- Cooling fluid can be channeled through extruded platen using C1M or C1 cooling applicator using plant water for quick cooling of the platen surface

Configurations

Add-Ons

Accessories

T6

T6

T2

T2

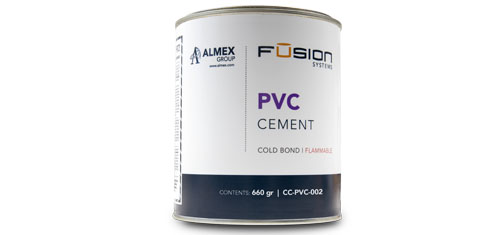

PVC Cold Bond Cement - Lightweight

PVC Cold Bond Cement - Lightweight

PVC Cold Bond Hardener - Lightweight

PVC Cold Bond Hardener - Lightweight

Flat White Bristle Cement Brush - 2"

Flat White Bristle Cement Brush - 2"

Related Items