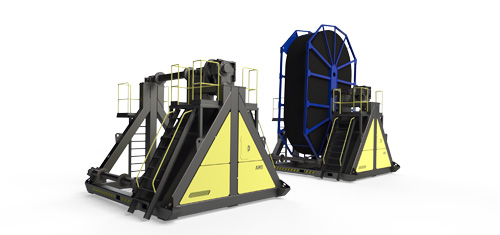

- The ultimate winder for plant belts.

- The go to winder for every day use.

- Handles a limited amount of steel cord belting.

- Variable speed control for added safety.

Proven & Reliable

Almex has been supplying the largest and most remote mining companies for over 60 years. Our equipment has a reputation of being designed for harsh environments and Almex winders have pulled the longest single belt in the world. Units are designed for years of reliable trouble free operation and can be provided with extended warranties.

Features and Options

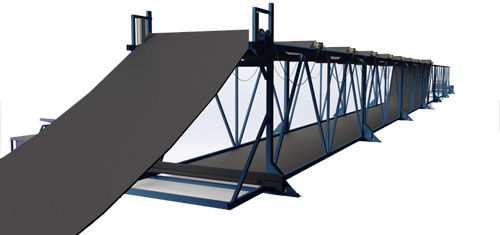

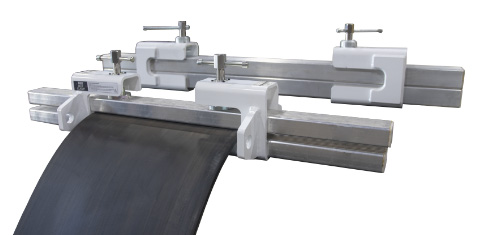

Almex can offer not only winders but belt stands, belt brakes, splice stations, vulcanizers pulling plates and splicing tools in a complete turnkey solution. Winder units can have stainless steel waterproof enclosures, remote tablet or pendant driven controls and Smart controls to monitor the operation and conditions of the units.

Custom Solutions

Applications for belt winders have unique requirements based upon the length of the conveyor, the width of conveyor belt, the pulling force and the diameter of the roll. Almex’s engineers provide custom designed units meeting the performance requirements of your system. Units are available with VFD, electric or hydraulic drive systems based upon budgets and operational requirements. Production is on 3 continents so deliveries can be accomplished to meet your timelines.

Safety and Quality

Conveyor belt pulling and winding is a very complex and high tension process. The stresses and forces exerted on the equipment are substantial. Almex uses only drives, couplings and frame construction that exceed standards to ensure the safety of the operators and protect your infrastructure, and all units are guarded and protected for operator safety. Commissioning and start-up services are available and Almex provides extensive documentation on operation, and maintenance of the units.

- The ultimate winder for plant belts. Mining, power plants, steel factories, aggregate, cement, grain, trash/recycling, agriculture, etc.

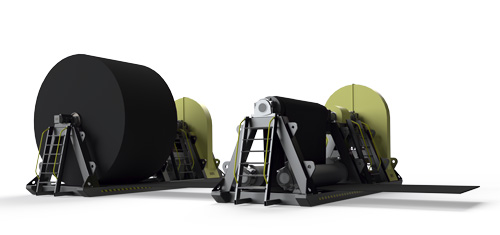

- This is you go to winder that you use every day. If it’s not an overland or a slope belt, and you can fit it behind, below, above, or in front of the conveyor this is the winder you need.

- Fill up the winder with the largest width and diameter fabric belt you can fit. Designed so you, or your crew, won’t hurt it.

- Can handle a limited amount of steel cord belting. Check the specifications.

- Enough power to get the job done.

- Variable speed control for added safety.

Features

Designed to fit on the width of the back of a Chevrolet 3500 or Ford 350 truck. You should also be able to load your press or gang box in winder. Get your guys and your equipment to site safely without extra vehicles or onsite setup time.

Product Information

Belt Winders are designed and manufactured according to the specifications required. Please contact your Sales Representative to discuss.

| Item | Specifications |

|---|---|

| Reel Specifications | |

| Max Reel Weight | 20 Tons |

| Max Reel Diameter | 144”/3.66 M |

| Max Belt Width | 64” /1625 mm |

| Winder Performance | |

| Line Pull at Hub | 7.8 Tons @ 14” ⌀ |

| Line Pull at Max Diameter | 0.8 Tons @ 144"⌀ |

| Maximum Reeling Speed | 5.8 RPM |

| Drive Torque at Reel | 10242 lb-ft / 13.9 kNm |

| Drive Specifications | |

| Electrical Motor Power | 12 HP / 9 kW |

| Motor Voltage | 480 VAC |

| Equipment Dimensions | |

| Length | 180” |

| Width | 88” |

| Height | 98” |

| Mass | 6.0 Tons |