Superspotter (SSP4)

ALMEX_IN_A_BOX

Superspotter (SSP4)

- Convenient spot repair press

- Field-portable

- Suitable for repairs to both fabric and steel cord belts up to 78” (2000 mm) wide

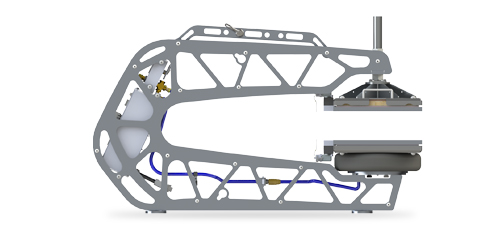

The Almex SuperSpotter (4th Generation) is a superior vulcanizing presses for heavy weight rubber belt maintenance. This field-portable press is ideal for repairing small tears and punctures. The SSP model is a `one-man’ repair press, allowing one person to carry the press to the repair location, assemble the vulcanizer, and effect the repair. The ease of transport and operation means a very fast cycle to minimize conveyor downtime.

Why Is Almex Different?

- Accomodates 60-78" wide belt

- Adjustable Platens

- Convenient Carry Case for platens and cables

- Quick Setup

- Low profile for repairs in confined locations

- Integral water cooling for faster repairs

Features

Features

- Signature Shaw Almex "Pressure Bag" uniform pressure system

- Custom "Extruded Plank" fast cooking system within platens

- Durable silicon heating element

- Lightweight and portable structure

- Suitable for repairs to both fabric and steel cord belts up to 2000mm (78”) wide Maximum pressure of 75 psi (5 kg/cm²)

Specifications

PLATENS

- Utilizes innovative Almex flexible platen constructed from extruded plank, silicone heating element and durable composite insulation

- Each platen contours to belt irregularities, ensuring uniform results. Maximum temperature 163 °C (325 °F)

- Available platen size: 300 mm x 300 mm (12”x 12”)

FRAME

- Welded aluminum C-Frame with handle for easy, one man handling

- Two sizes are available for use on belt widths up to 1500 mm (60”) and 2000 mm (78”)

- Complete with platen carrying case.

PRESSURE/COOLING

- Almex pressure bag ensures uniform pressure across splice surface. Maximum operating pressure 5 kg/cm² or 75 psi

CONTROL PANEL

- Thermostatic control panel pre-set with dual voltage standard. Also available with remote and CE approved controls

Configurations

Accessories

Filler Rubber

Filler Rubber

HC1 Vulcanizing Splice Cement

HC1 Vulcanizing Splice Cement

Fabric Belt Cover Stock

Fabric Belt Cover Stock

HST Splice Surface Prep

HST Splice Surface Prep

HFP Vulcanizing Splice Fabric Primer

HFP Vulcanizing Splice Fabric Primer

Related Items